The research activities of mCD focus on the development and characterization of cement materials and on the durability of reinforced concrete structures.

-

Concrete and cementitious materials:

New cements and additions for sustainability

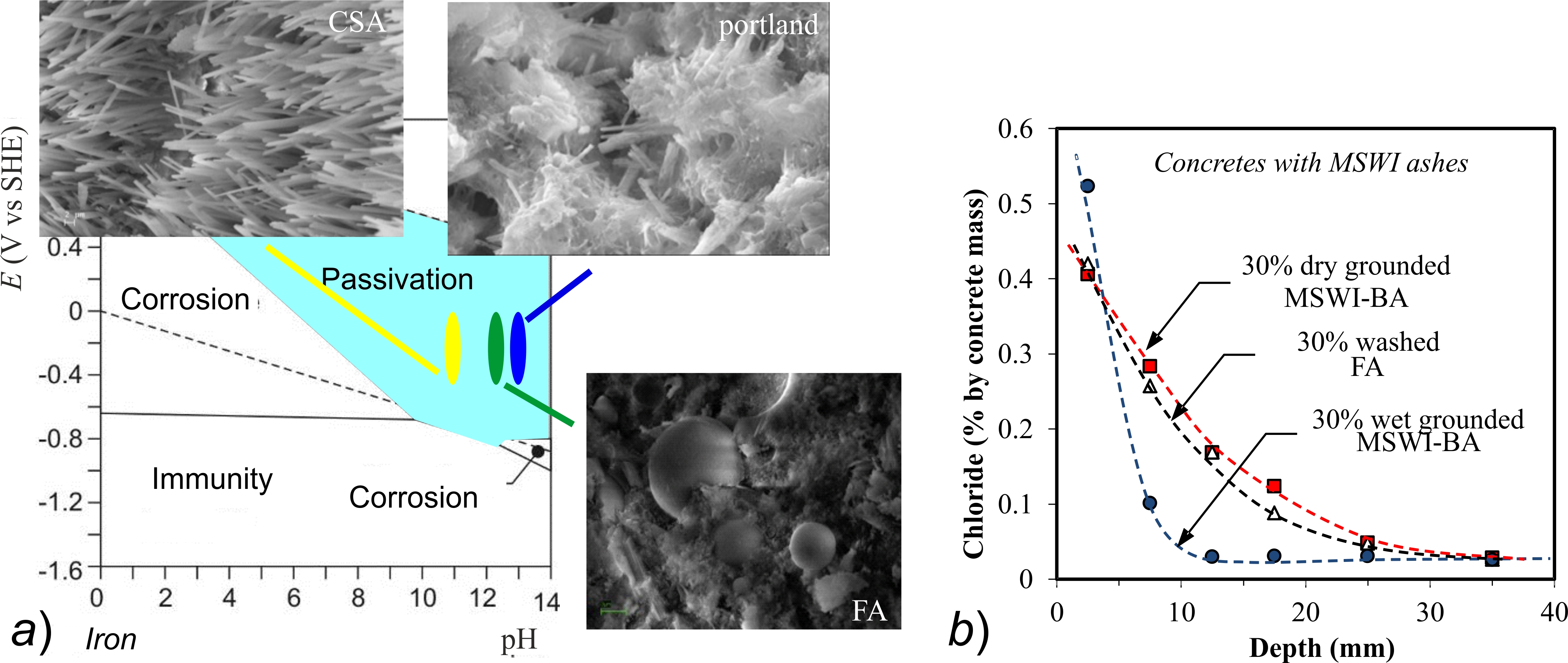

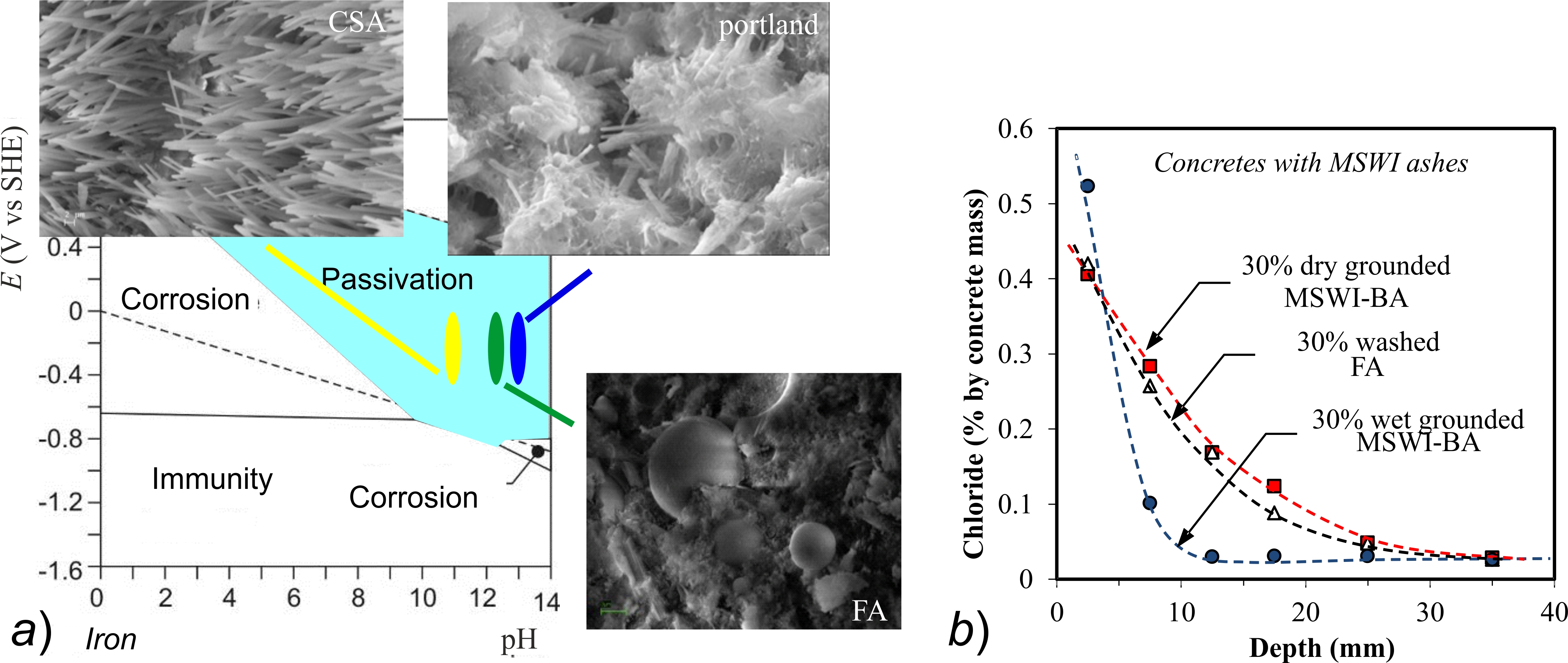

A research field of mCD group concerns the study of new cements and mineral additions to use in concrete; different studies carried out, both in the past and in progress, are aimed at evaluating the effect of different mineral additions on corrosion of reinforcement concrete structures. Both traditional mineral additions (such as carbon fly ash, silica fume and natural pozzolans) or innovative (such as bottom ash from incineration plants or glass powder) have been studied. The use of bottom ash from incineration plants in concrete have been studied; these municipal solid wastes, having inside metallic aluminum, need to be finely ground (in the form of slurry) so that the reaction of hydrogen development can be depleted and the slurry could be used in concrete as mineral addition.

Also sulfoaluminate cements have been studied; these cements, lowering the pH of concrete, could influence the passivation of embedded steels in concrete and its protection against corrosion.

Corrosion behaviour of steel as a function of pH of pore solution and role of different types of cements in terms of protection capacity on the reinforcement in concrete (a) and penetration profiles of chlorides in concrete with different types of mineral additions (fly ash and bottom ash from municipal solid waste incineration, after dry and wet grinding) (b)

Special Concrete

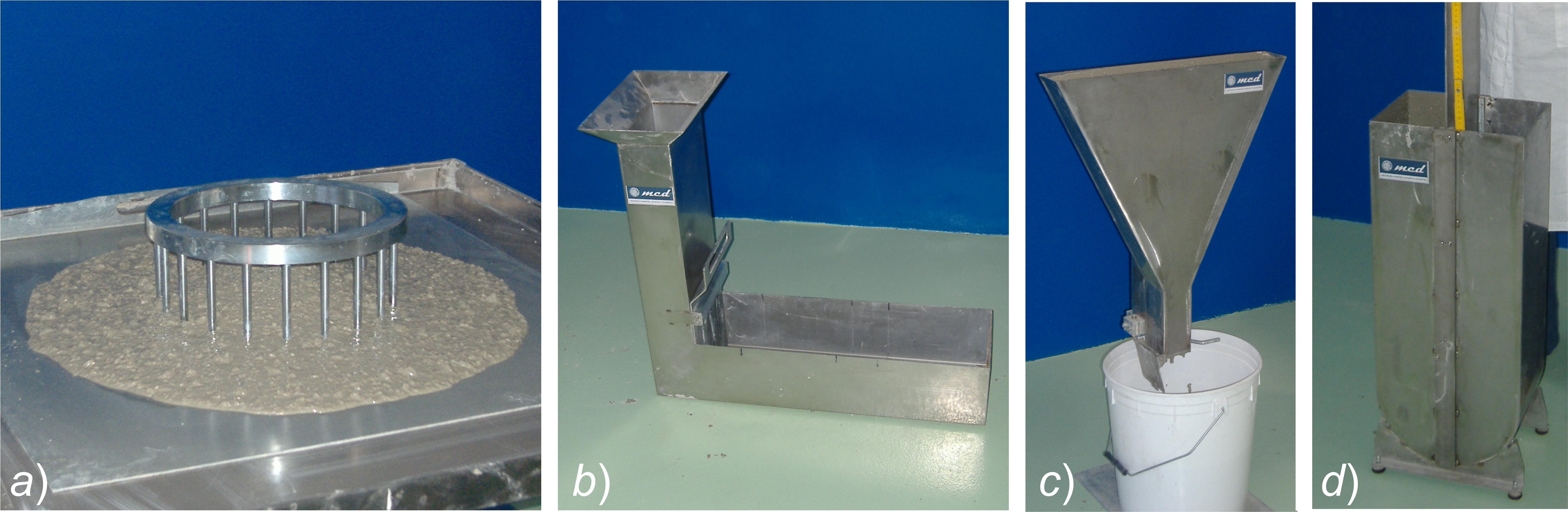

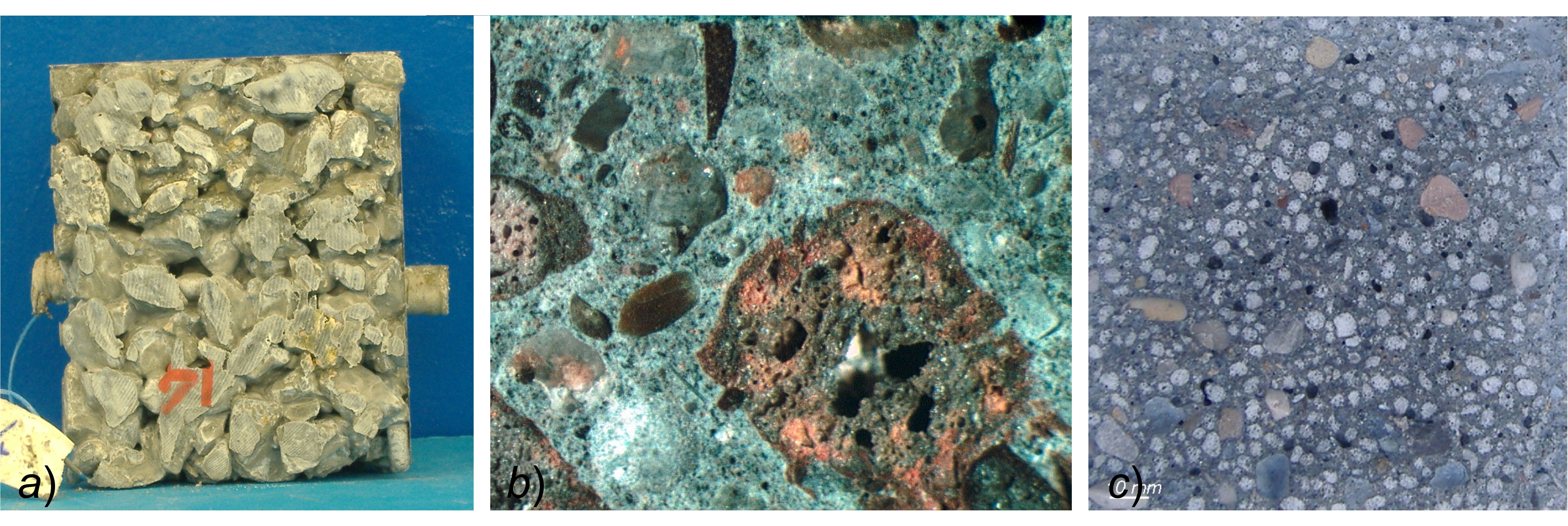

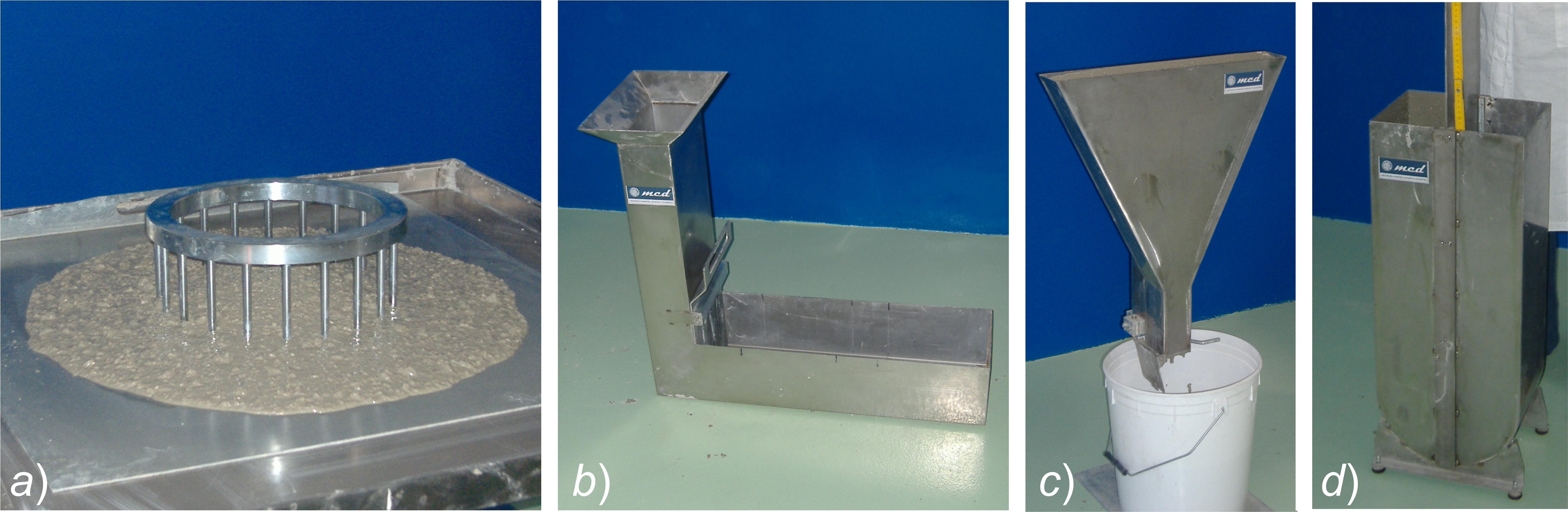

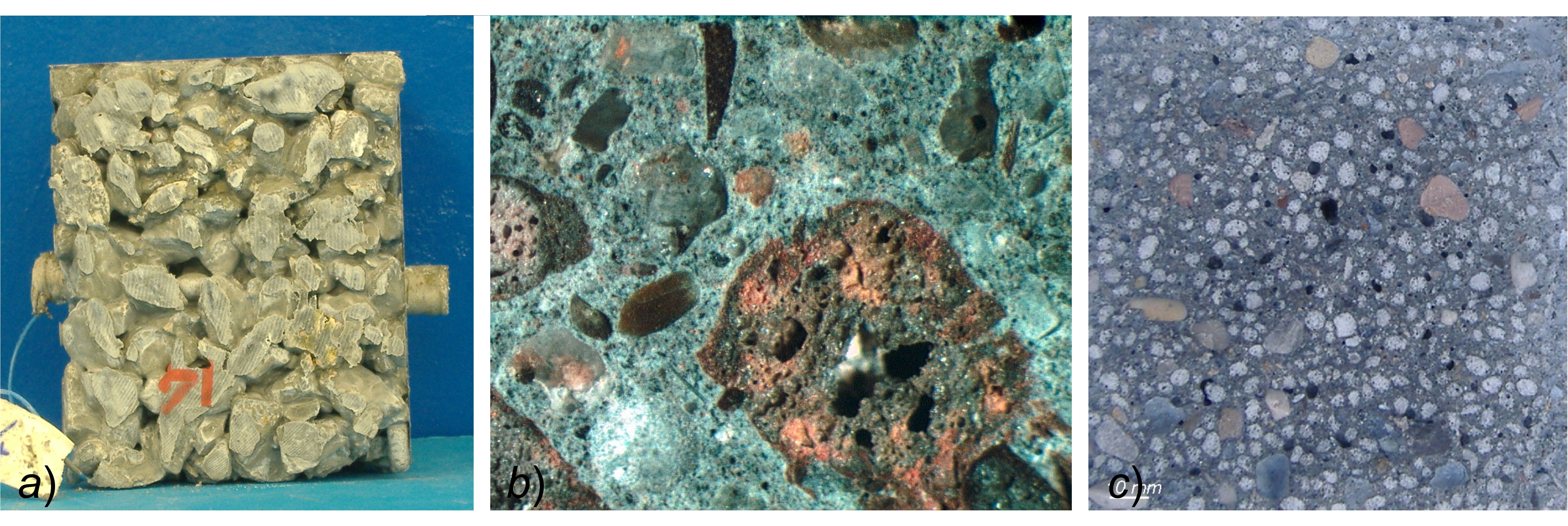

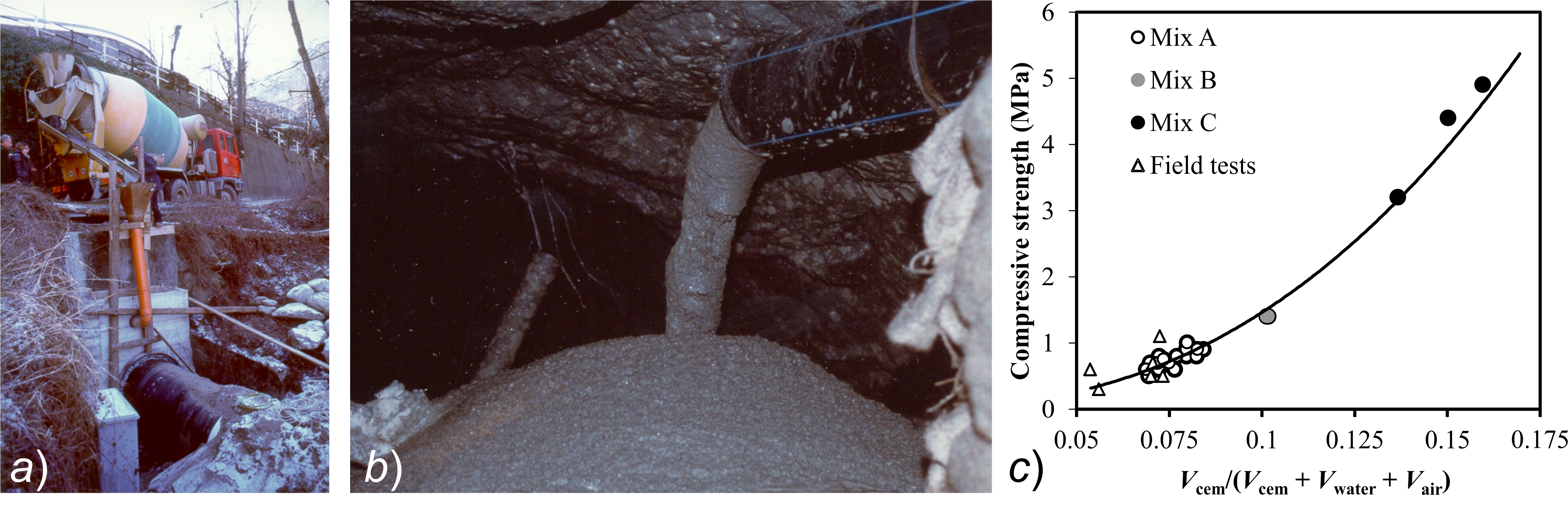

Performance and durability properties of self-compacting concrete (SCC), light-weight concrete (such as no-fines concrete and those made with expanded clay and expanded glass aggregates), cementitious materials suitable for backfilling of mini-tunnels and mines (such as controlled low strength materials (CLSM) and flowable soil-cement mixtures) have been studied. Moreover, corrosion behaviour of steel reinforcement embedded in these innovative cementitious materials has been evaluated.

Workability test of self-compacting concretes: J-ring (a), L-box (b), V-Funnel (c) and U-box test (d)

Light-weight concrete made (a) without fine aggregates (no-fines concrete) or by replacing partially the ordinary aggregates with expanded clay (b) or expanded glass (c)

Flowable soil-cement mixtures (a-b) and compressive strength of flowable cement-soil mixes made with different soils as a function of the water to cement ratio (w/c), after 7 and 28 days of different curing conditions (c)

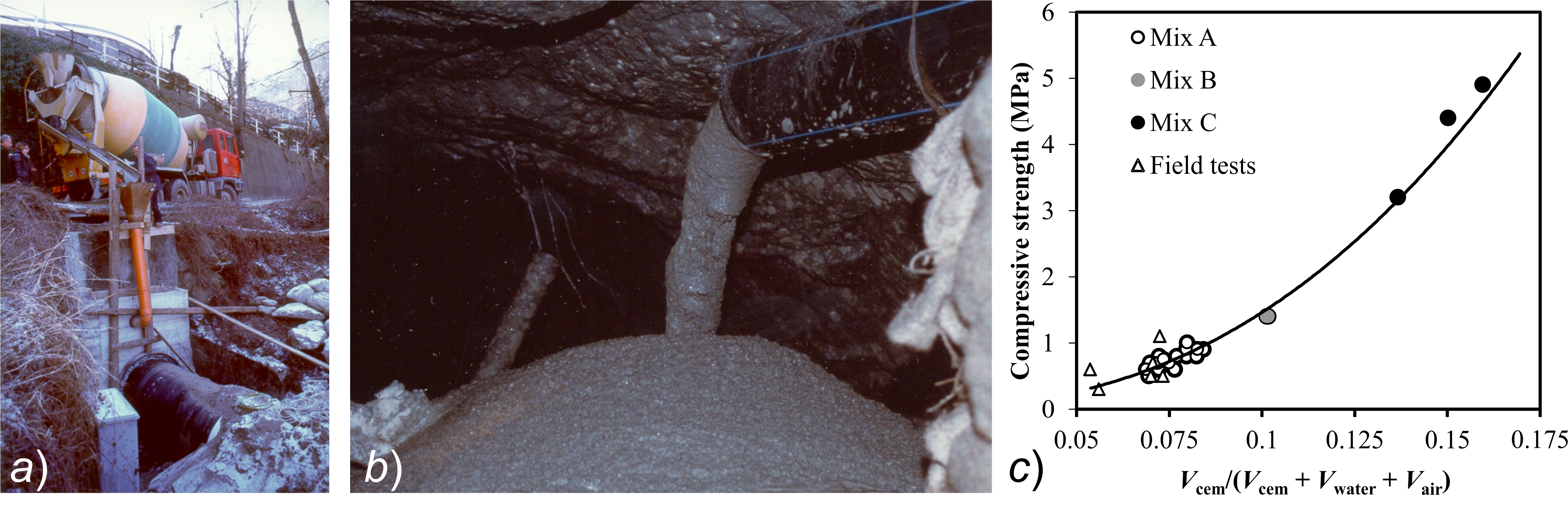

Controlled low strength materials (CLSM) for backfilling of mini-tunnels hosting a pipelines (a-b) Experimental relationship between 28-day compressive strength and ratio of volume occupied by cement (Vcem), water (Vwater), and air (Vair), for different CLSM mixes

Materials for rehabilitation

repair mortars / surface treatments / externally bonded FRP

Examples of materials used for rehabilitation: repair mortar (a), surface treatment (b) and bonded F.R.P. (c)

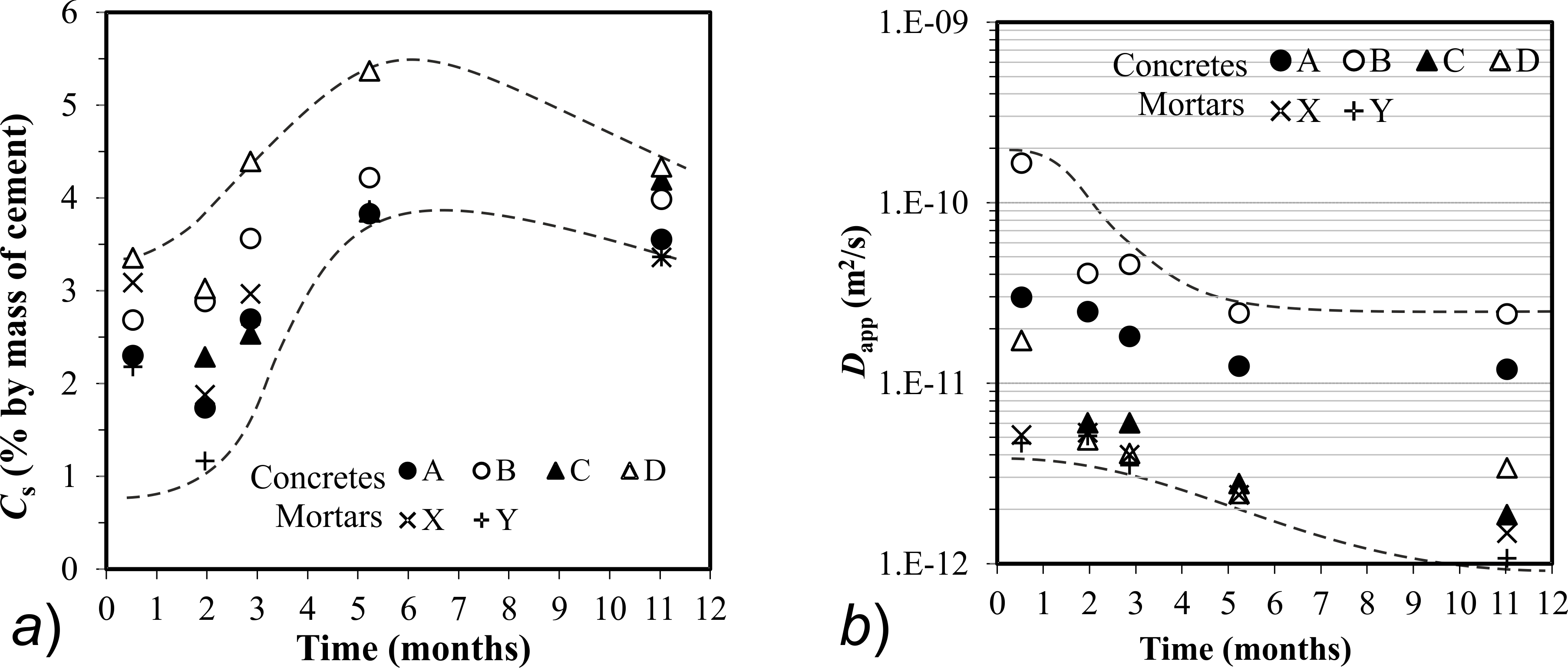

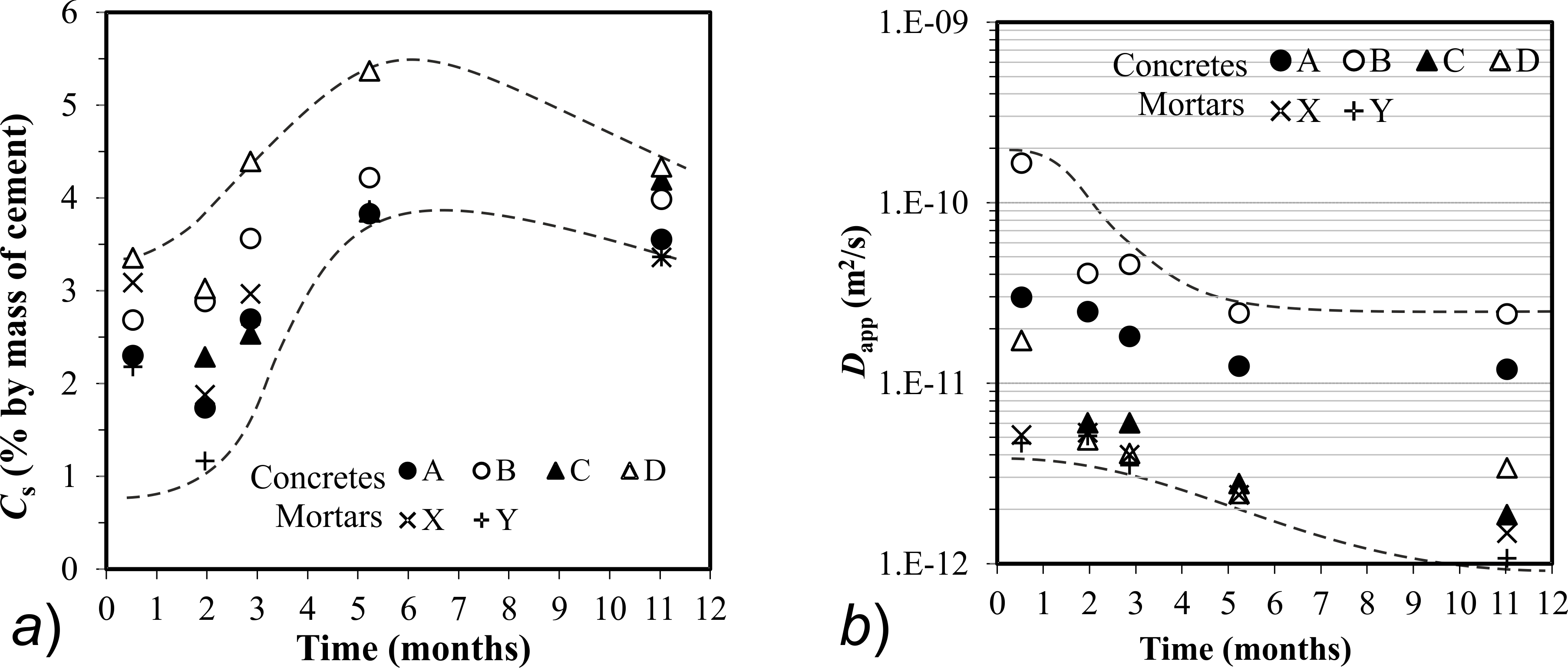

Surface chloride contents (a) and apparent diffusion coefficient (Dapp) (b) calculated from chloride profiles measured on the tested materials after different times of exposure to chloride cycles

-

Durability of reinforced concrete structures :

Corrosion of steel in concrete

The mCD group pays special attention to corrosion induced by carbonation and by chlorides penetration,through the study and definition of the different factors which influence the initiation and the propagation and the modelling of the evolution of the phenomena.

Corrosion due to stray currents and hydrogen embrittlement of reinforcement, as well as the effects of galvanic couples, have been also studied.

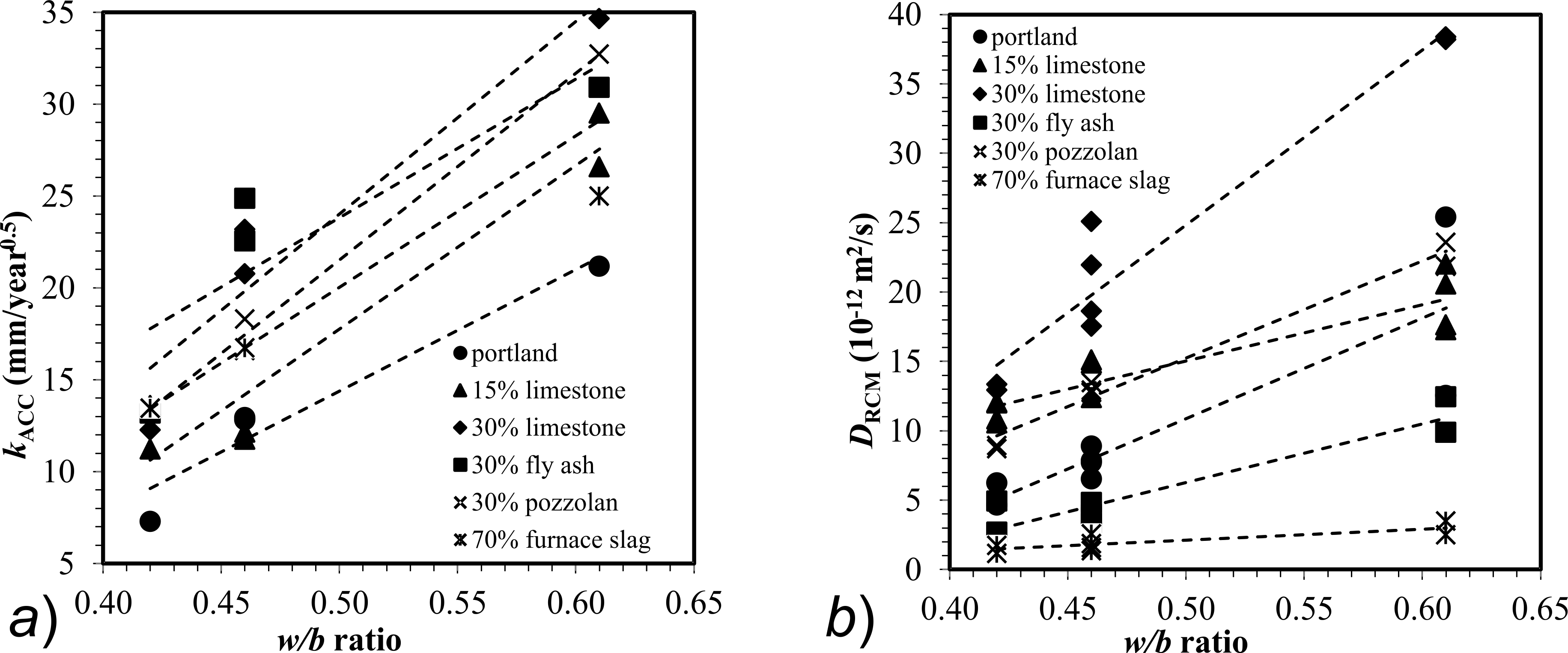

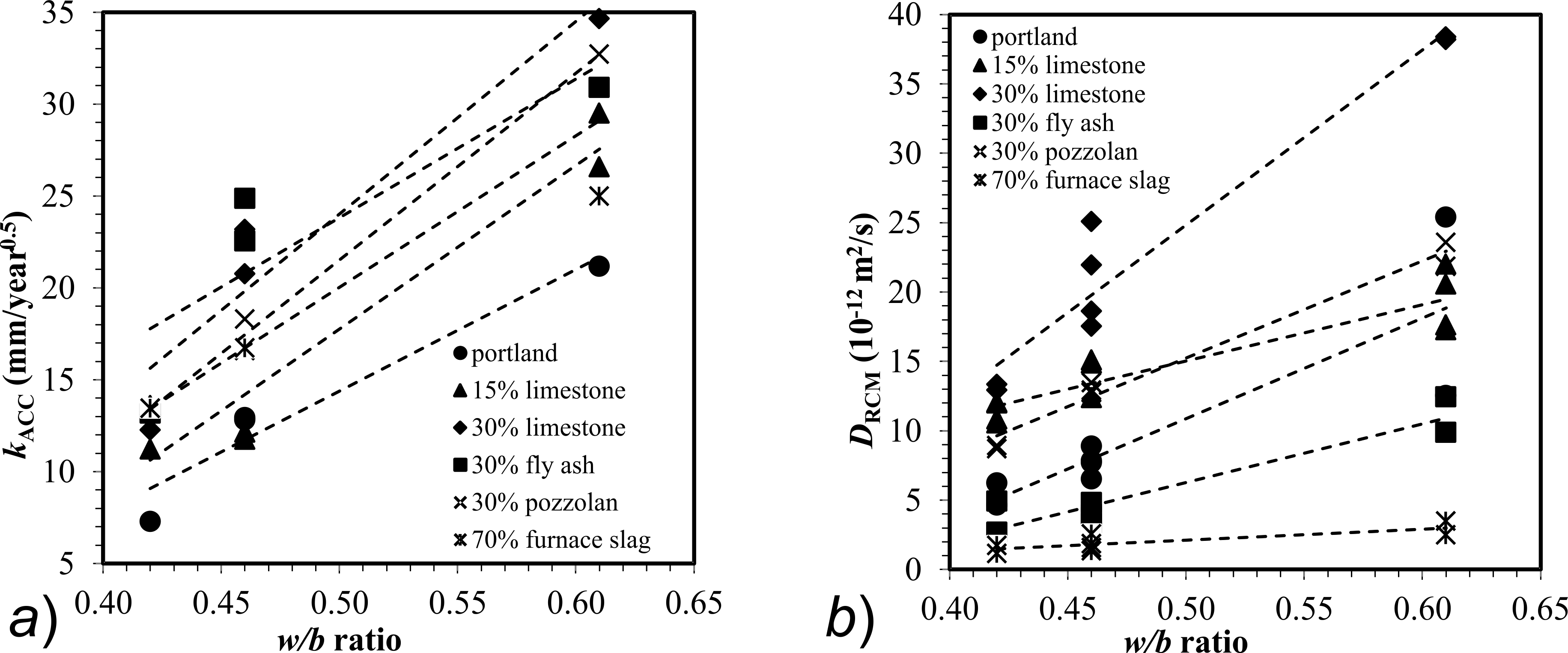

Accelerated carbonation coefficient (a) and diffusion coefficient evaluated by means of the rapid chloride migration test (b) for different types of concrete

Example of stray currents interference

Design for durability

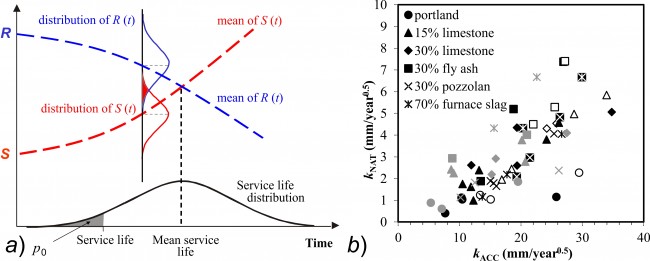

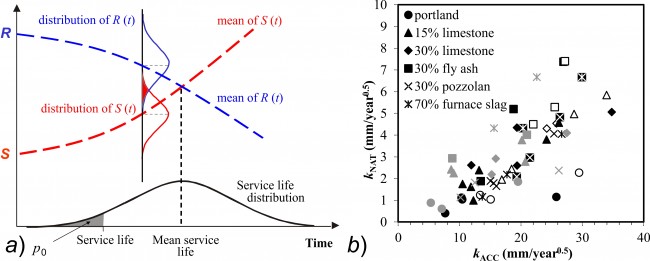

The awareness that reinforced concrete structures have to be designed to satisfy the durability requirements, has given a strong impulse in the development of models which allow the evaluation of the service life of a structure. The mCD group is active in this front, studying and analyzing the available models to design durable structures, to evaluate their reliability as well as their weakness, thatlimit presently a widespread use of them.

Experimental results of in progress researches have been used to overcome these limits; for instance, taking into account the use of preventative measurements, such as galvanized and stainless steel.

Probabilistic approach for the evaluation of the service life of a reinforced concrete structure (a) and relationship between the carbonation coefficient evaluated in accelerated and natural conditions (b)

Electrochemical techniques

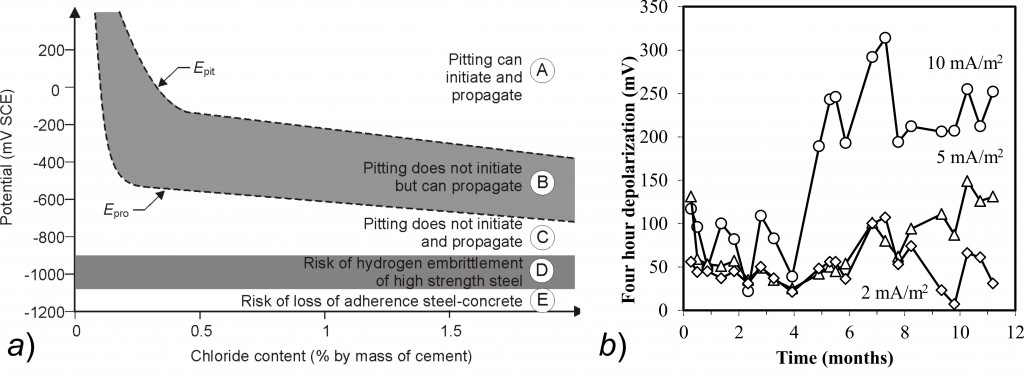

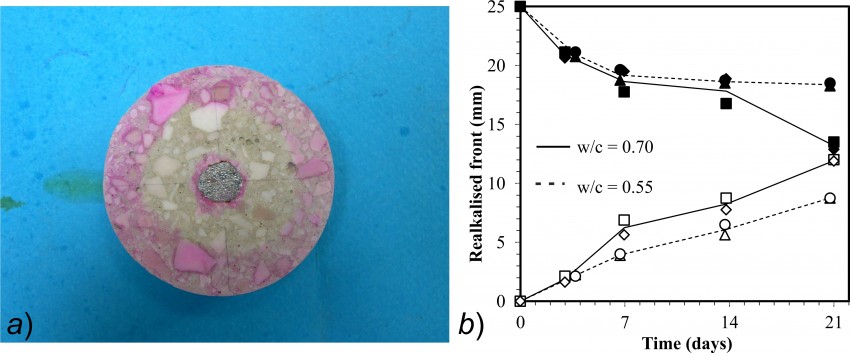

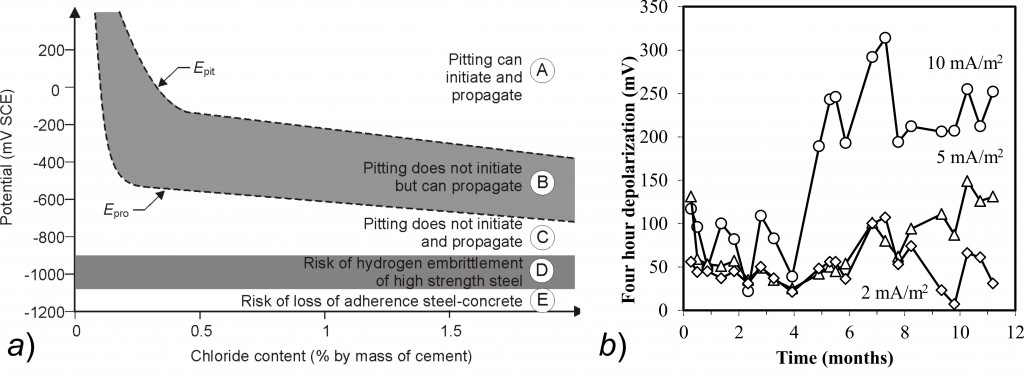

Electrochemical techniques are based on the application of a current to reinforcement embedded in concrete and allow to increase the service life, delaying the initiation of corrosion in new structures or interrupting the propagation of corrosion in existing structures. For instance, cathodic prevention, which was introduced and finalized in this group by prof. Pietro Pedeferri, allows to increase the amount of chlorides needed to initiate corrosion and, nowadays, it is used internationally to prevent corrosion on structures exposed to harsh environments due to the presence of chlorides. Cathodic protection is used on existing structures and allows to interrupt the corrosion of reinforcement in contact with non-protective concrete (carbonated or contaminated by chlorides). Furthermore temporary electrochemical techniques are available; they allow to restore the protective characteristic of the concrete in contact with bars. One of these techniques, the electrochemical realkalisation, could be used to interrupt the corrosion phenomena of structures exposed to the atmosphere that suffer carbonation induced corrosion, at least when the extent of damage is limited. This technique was studied by means of experimental tests and applied in situ to existing structures, such as the Church of Santa Maria Annunciata of the San Carlo Hospital in Milan, designed by Gio Ponti, and the Church of Sant’Antonio abate in Valmadrera.

Pedeferri’s diagram showing areas of corrosion (A), imperfect passivity (B) and perfect passivity (C) as a function of rebar potential and chloride content (a) and evolution of four hour depolarisation of rebar in carbonated concrete for various applied cathodic current densities (b)

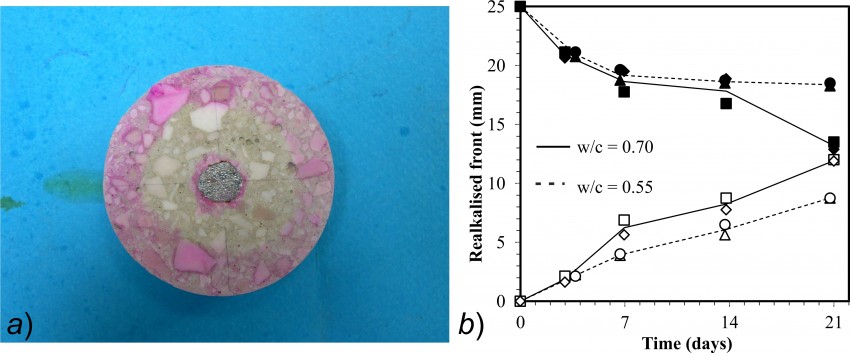

Phenolphthalein test on initially carbonated concrete subject to realkalisation (a) and evolution of internal and external realkalised fronts in concretes with different w/c ratio (b)

Stainless steel rebars

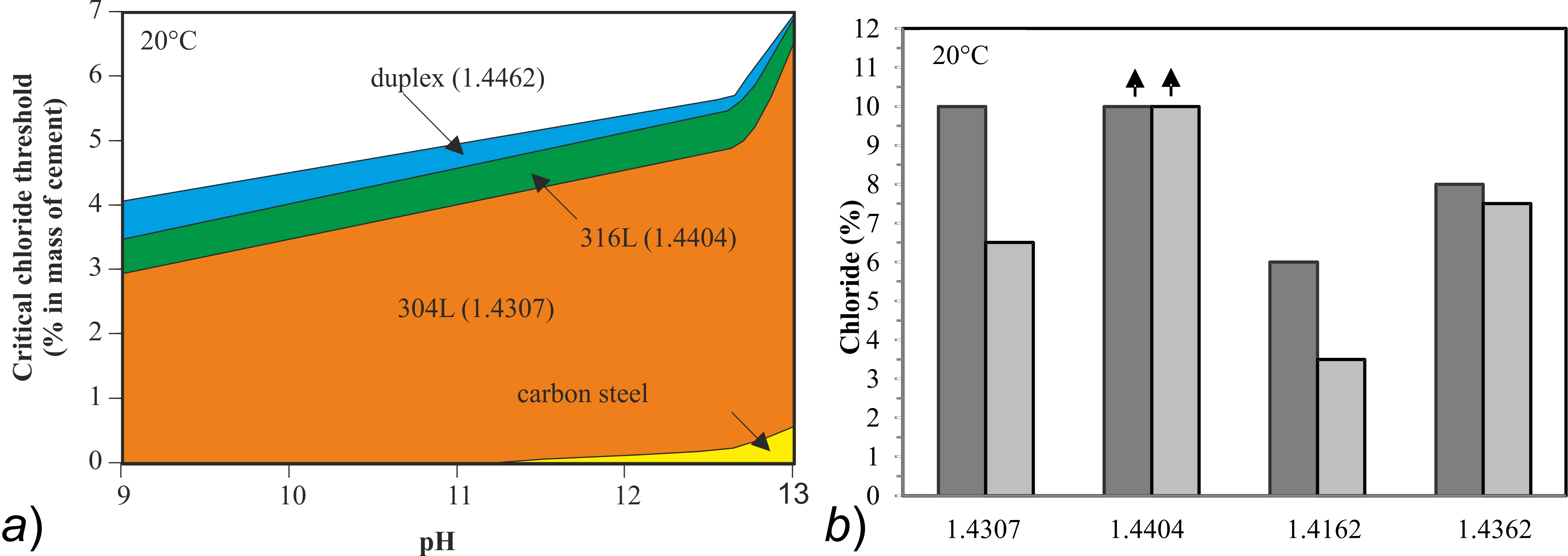

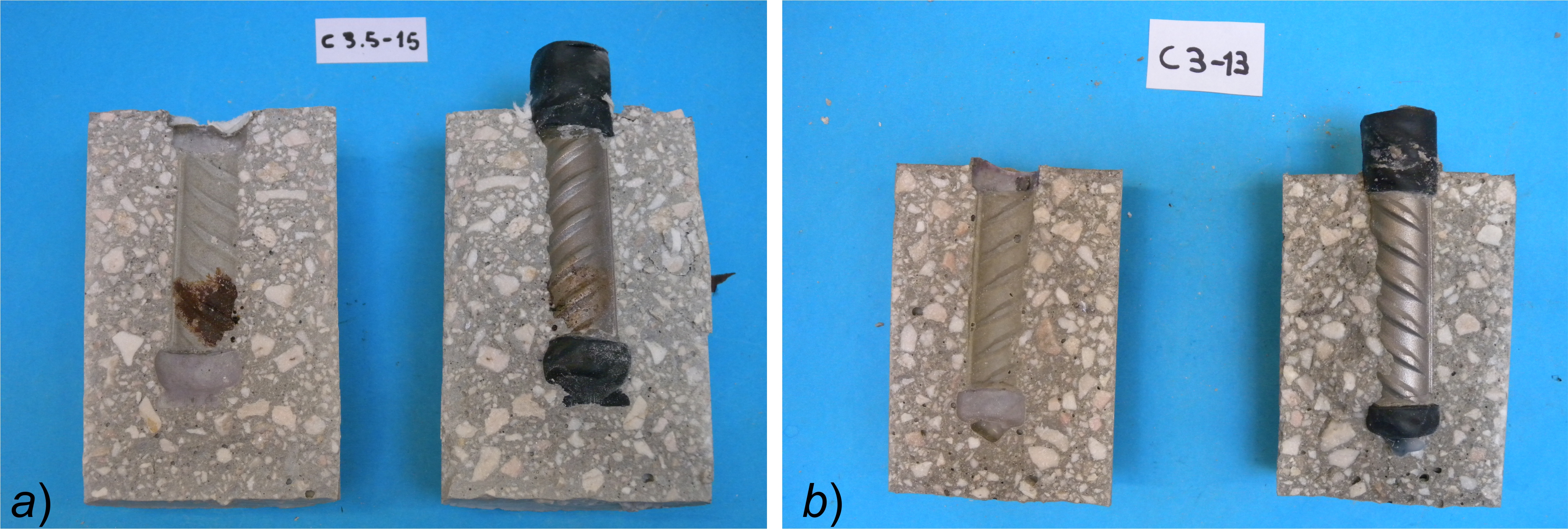

The use of stainless steel reinforcement can be an effective strategy to ensure the durability performance of reinforced concrete structures exposed to aggressive environments, especially in chloride bearing environments, or when a long service life is required. Thanks to the alloy elements, they have a higher corrosion resistance than that of carbon steel.

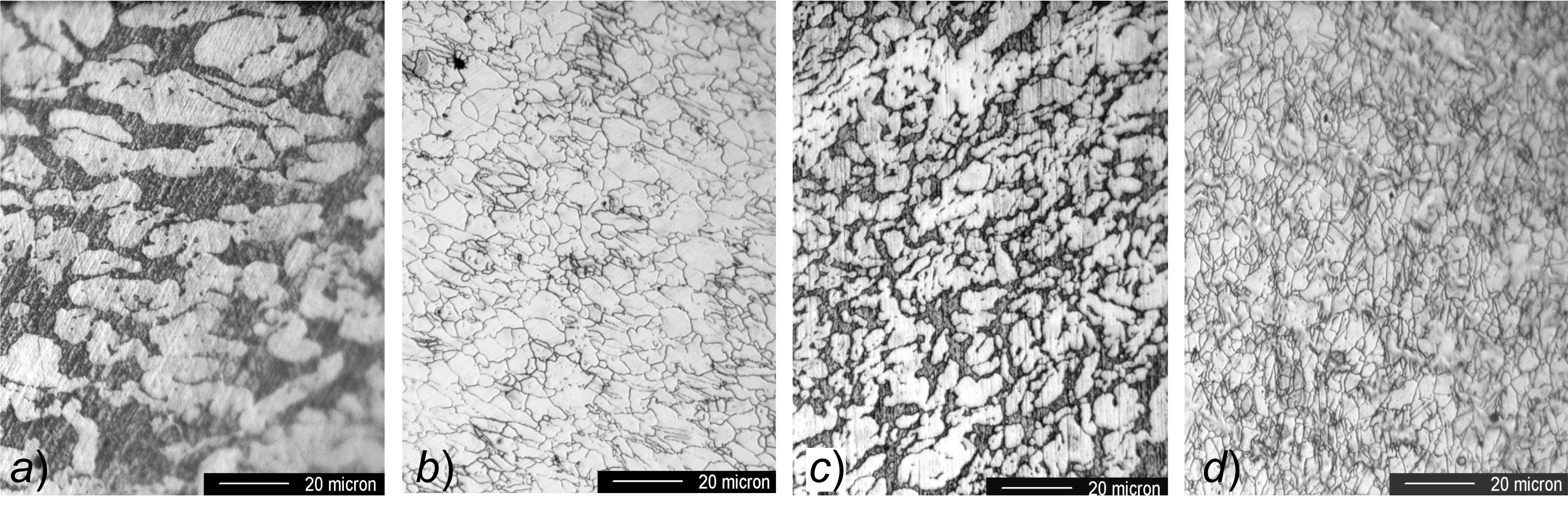

In the last decades, the research activity of mCD group has dealt with the corrosion behaviour of the stainless steel reinforcement. The research started considering mainly austenitic stainless steel bars, then austeno-ferritic (or duplex) and low nickel stainless steels were studied. Galvanic coupling phenomena, that can occur when ordinary steel and stainless steel reinforcements are used together, was also analysed. An experimental research, aimed at developing a test procedure that allows to evaluate the probability density function of the critical chloride threshold for the corrosion initiation on different types of stainless steel, is in progress.

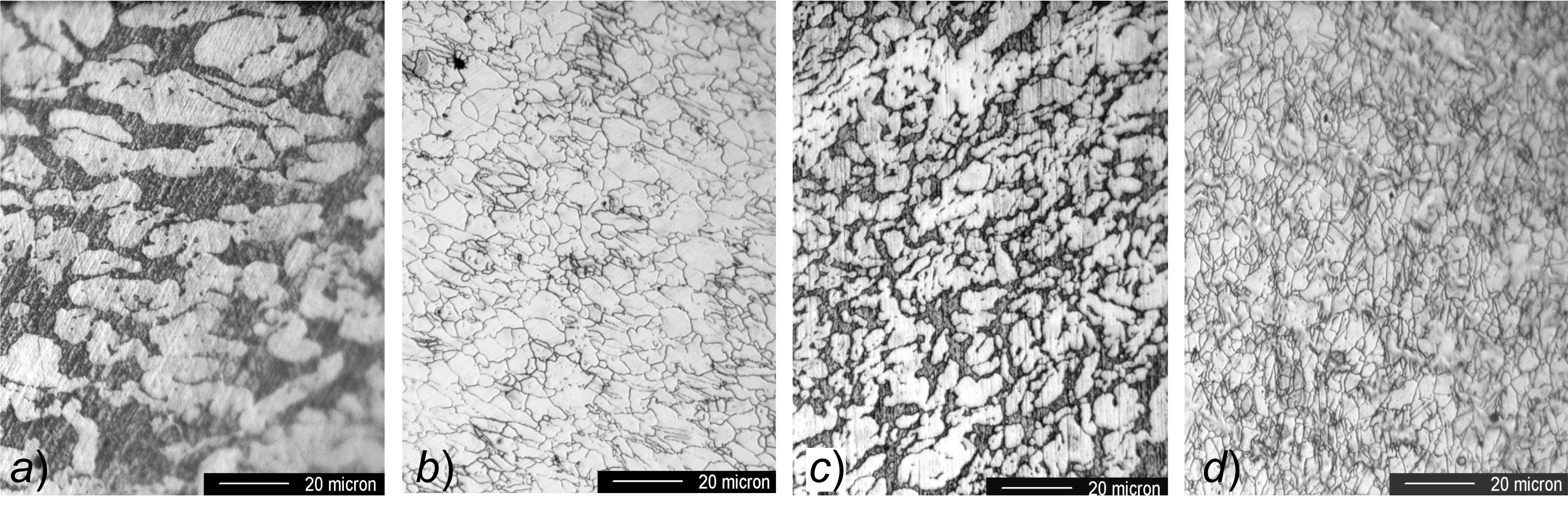

Microstrutture of different stainless steel grade: 1.4162 (a), 1.4311 (b), 1.4362 (c), 1.4406 (d)

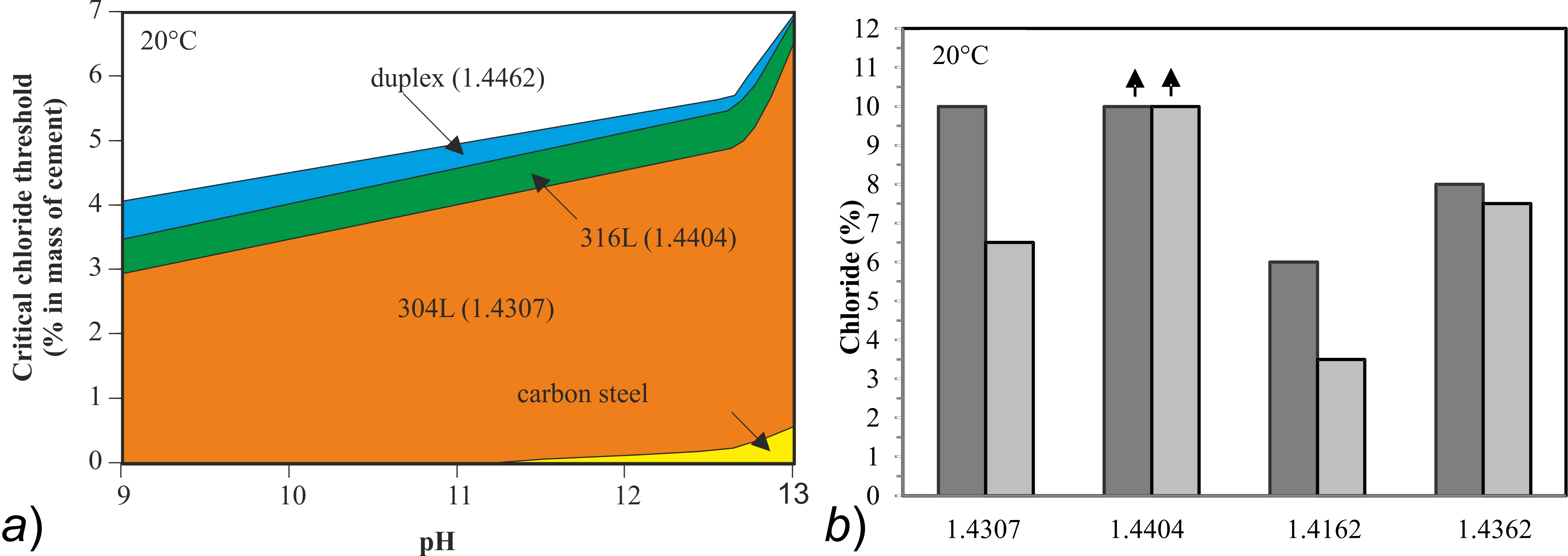

Schematic representation of fields of applicability of different steels at 20oC (a) and chloride content for pitting corrosion initiation in anodic potentiostatic polarisation tests (+200 mV vs SCE) in alkaline solution (pH 12.6) at 20oC (b)

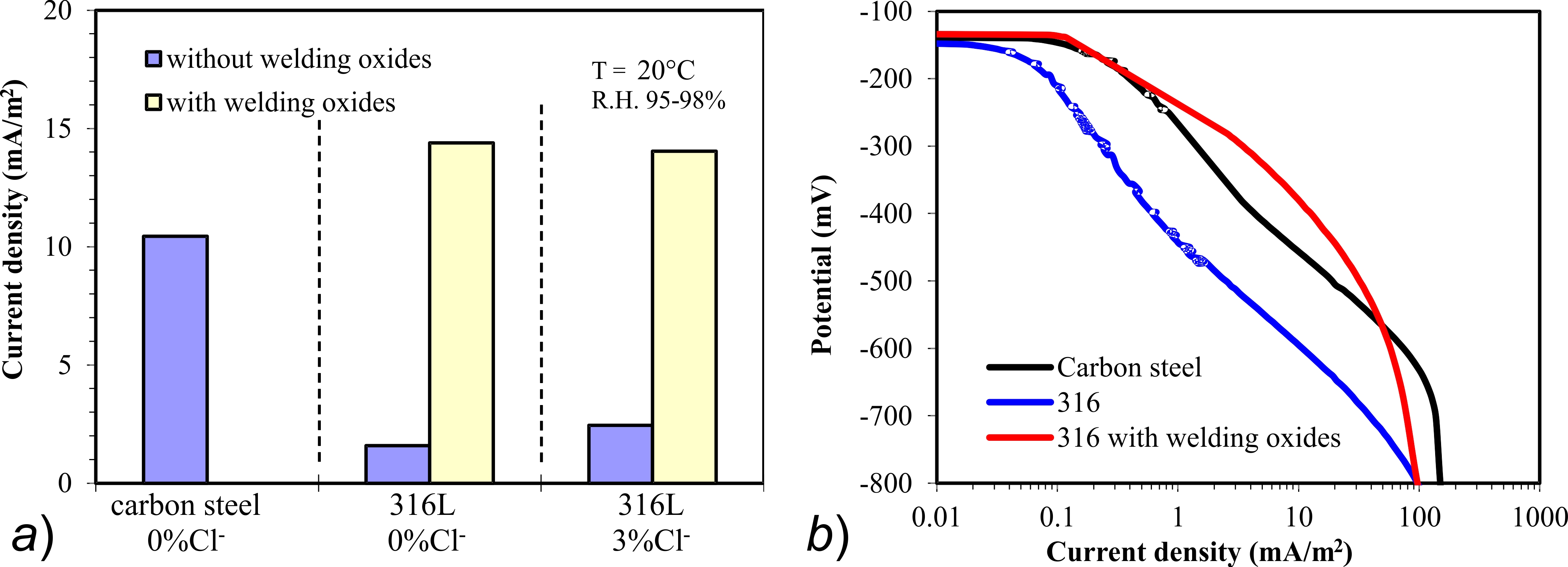

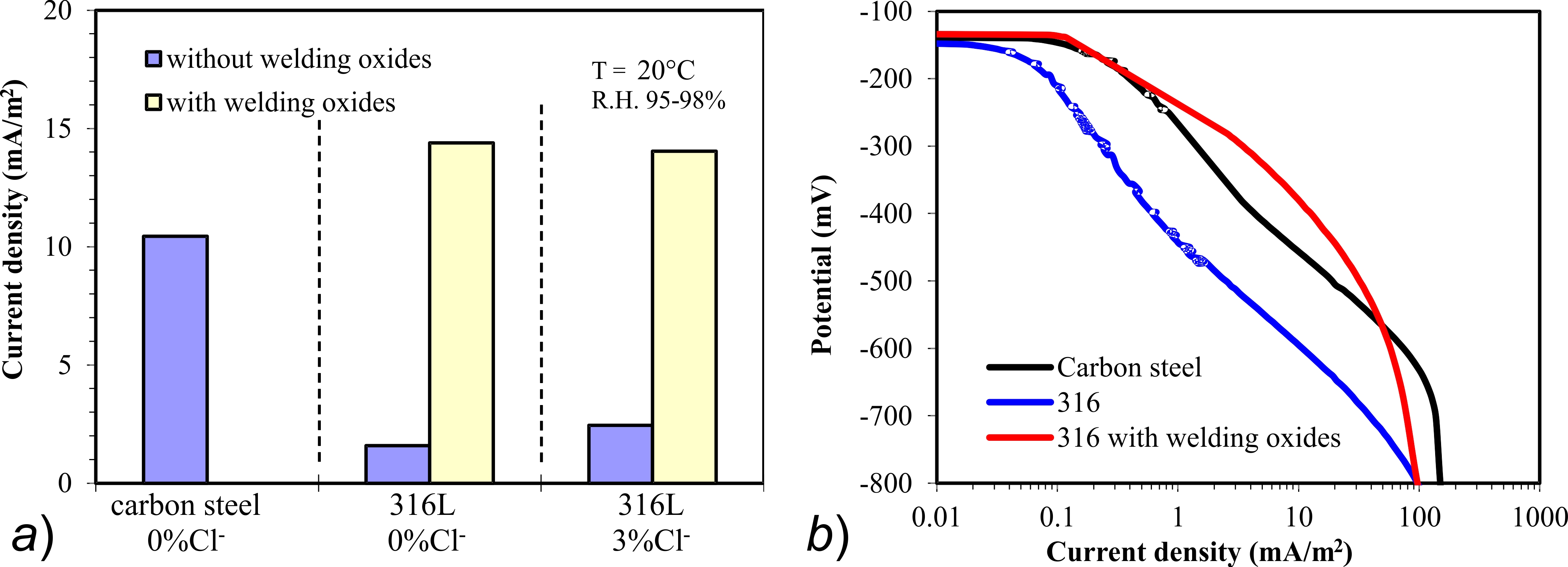

Macrocell current density exchanged between a corroding bar of carbon steel in 3% chloride contaminated concrete connected with a (parallel) passive bar of: carbon steel in chloride free concrete, on 316L stainless steel in chloride free concrete or in 3% chloride contaminated concrete (20oC 95% R.H.). Results on stainless steel bars with simulated welding scale are also reported (a) and cathodic polarization curves in alkaline solution (pH 12.6) of 316L stainless steel compared with the curve of carbon steel. Tests on stainless steels with simulated welding scale are also shown (b)

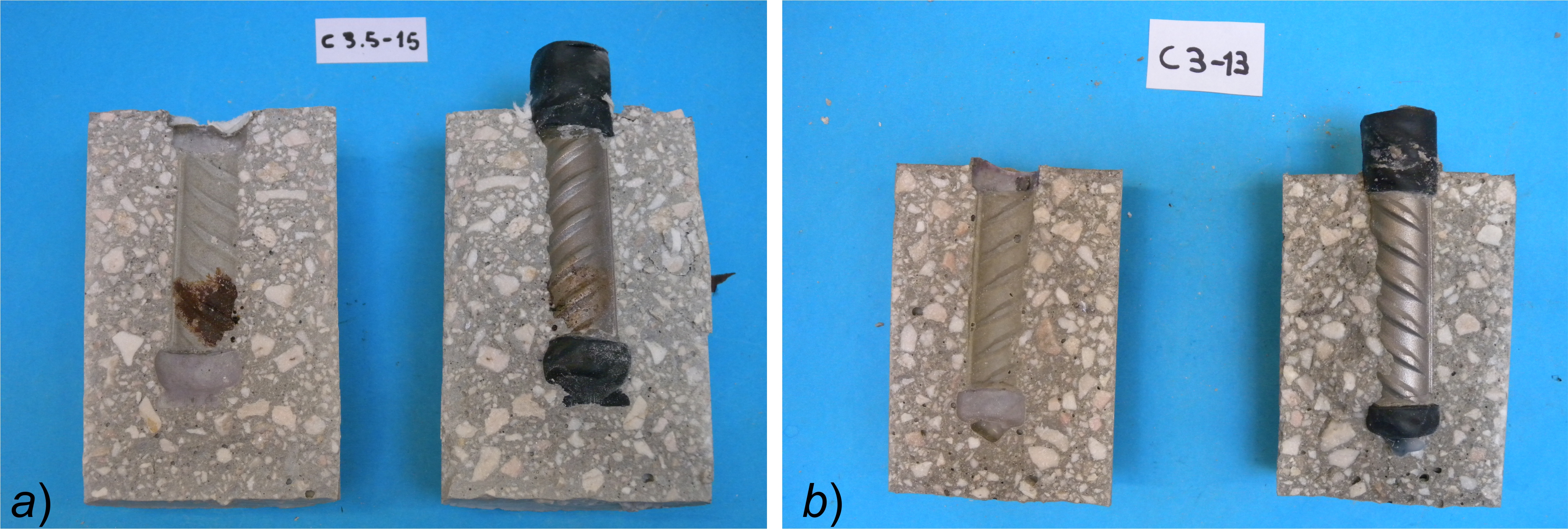

Test for the evaluation of the critical chloride threshold for corrosion initiation of stainless steel reinforcement in concrete: rebar with pitting corrosion initiation (a) and without corrosion (b)

-

Preservation of cultural heritage:

Characterization of ancient mortars and concretes

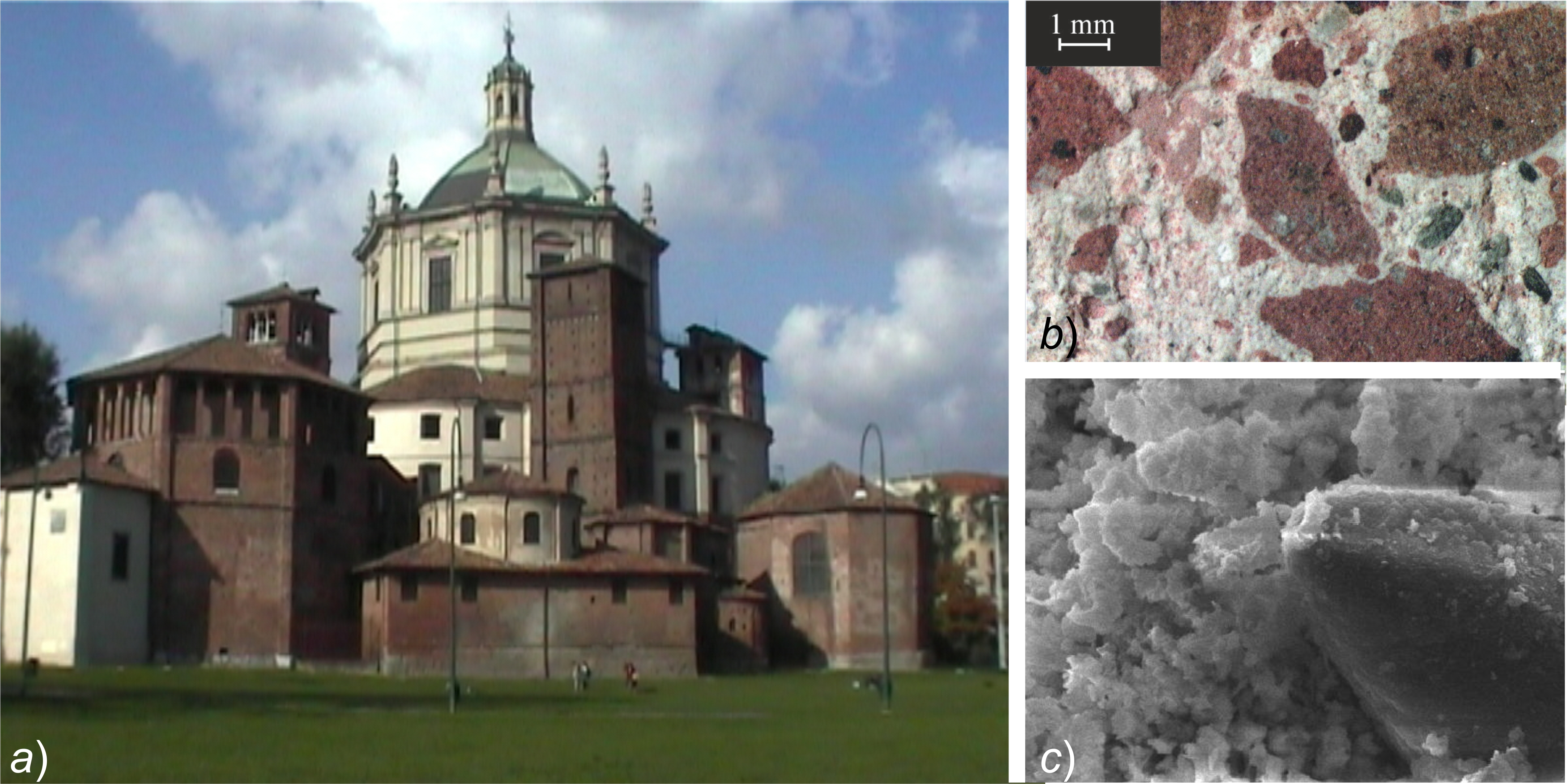

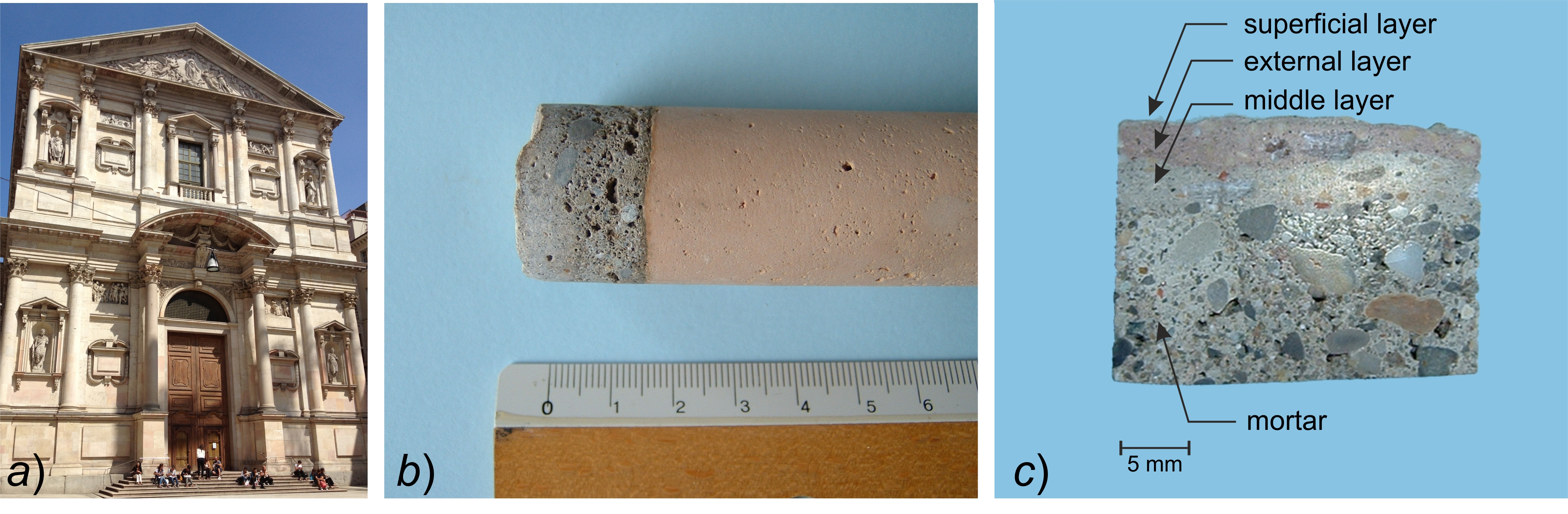

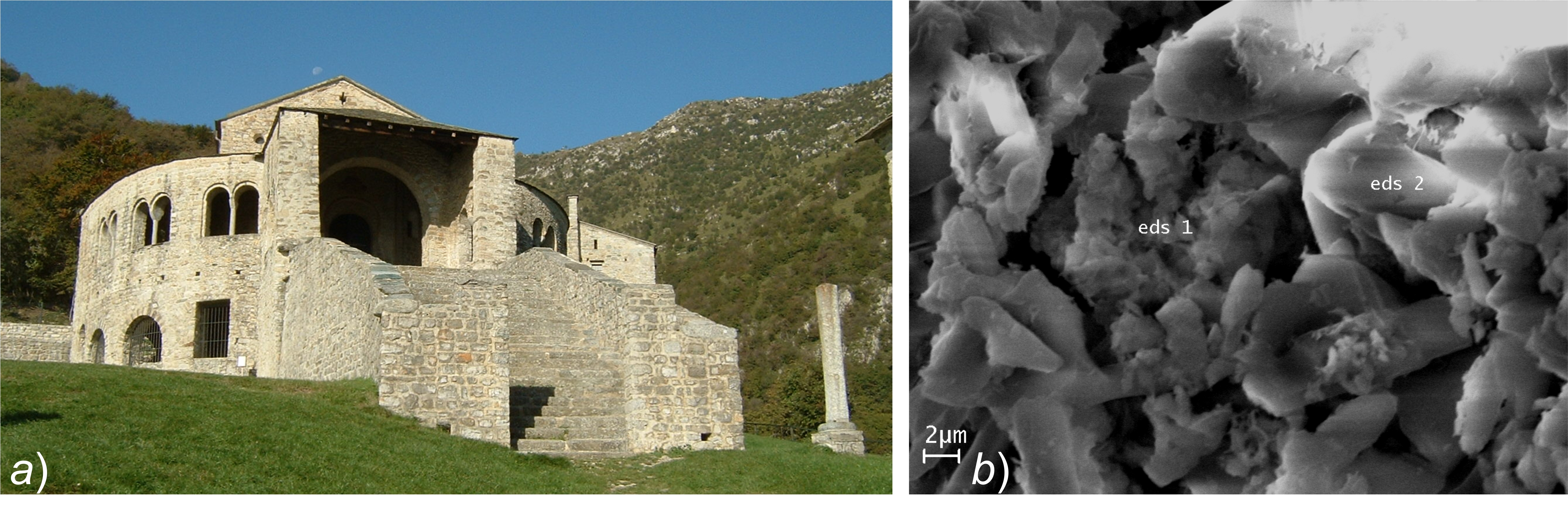

The studies on the preservation of cultural heritage concerned the inspection of structures, which have been included in the cultural heritage because of their architectural or social relevance, and the study of ancient concretes and mortars. The research group has been involved in various restoration projects related, for example, to the Basilica of San Lorenzo in Milan (built between IV and XVI century) and San Fedele Church in Milan (16th century) or the San Pietro Abbey (attributed to 11th century) in Civate.

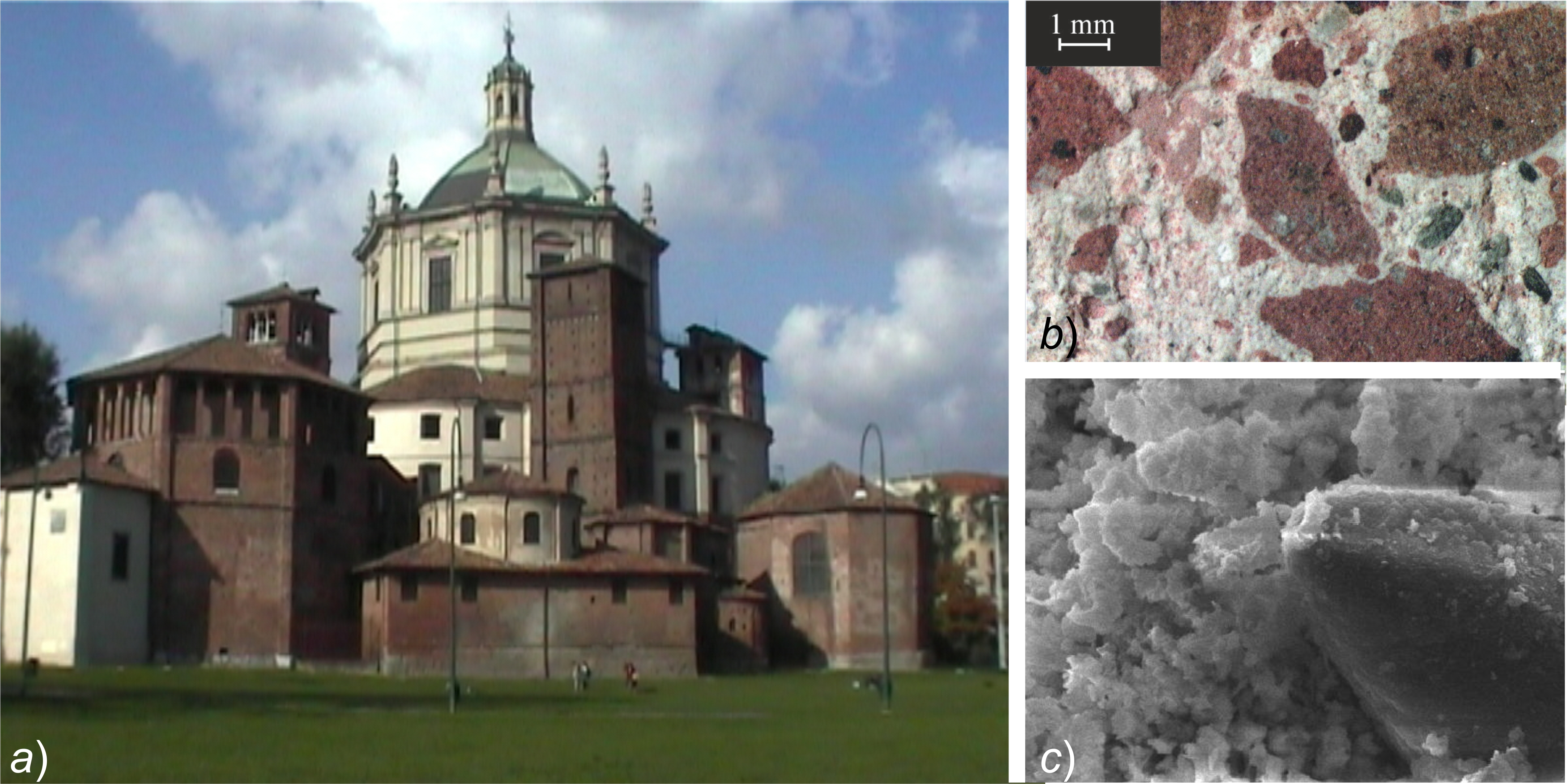

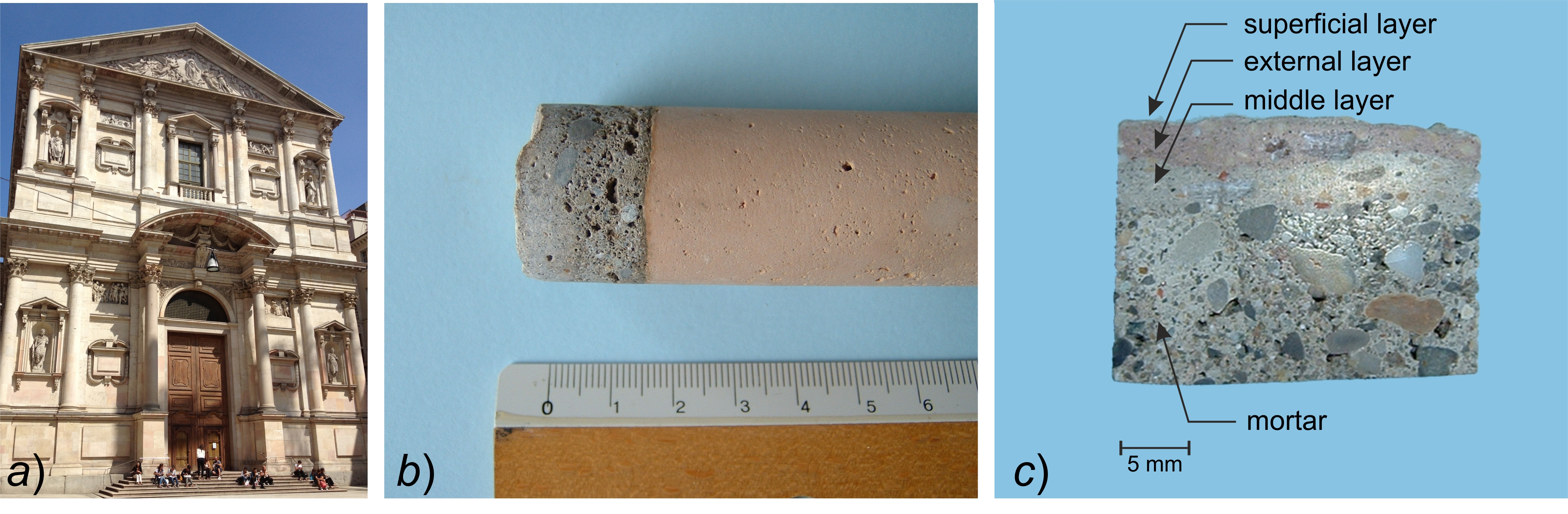

San Lorenzo Church (a) and stereomicroscopy (b) and SEM observation (c) of samples of ancient mortars

San Fedele Church (a) and macroscopy observation of samples of decorative cementitious materials (b-c)

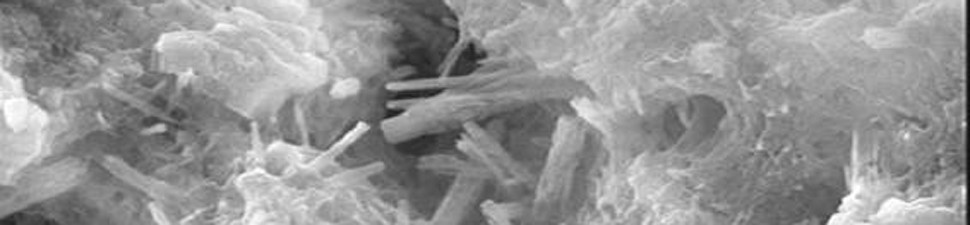

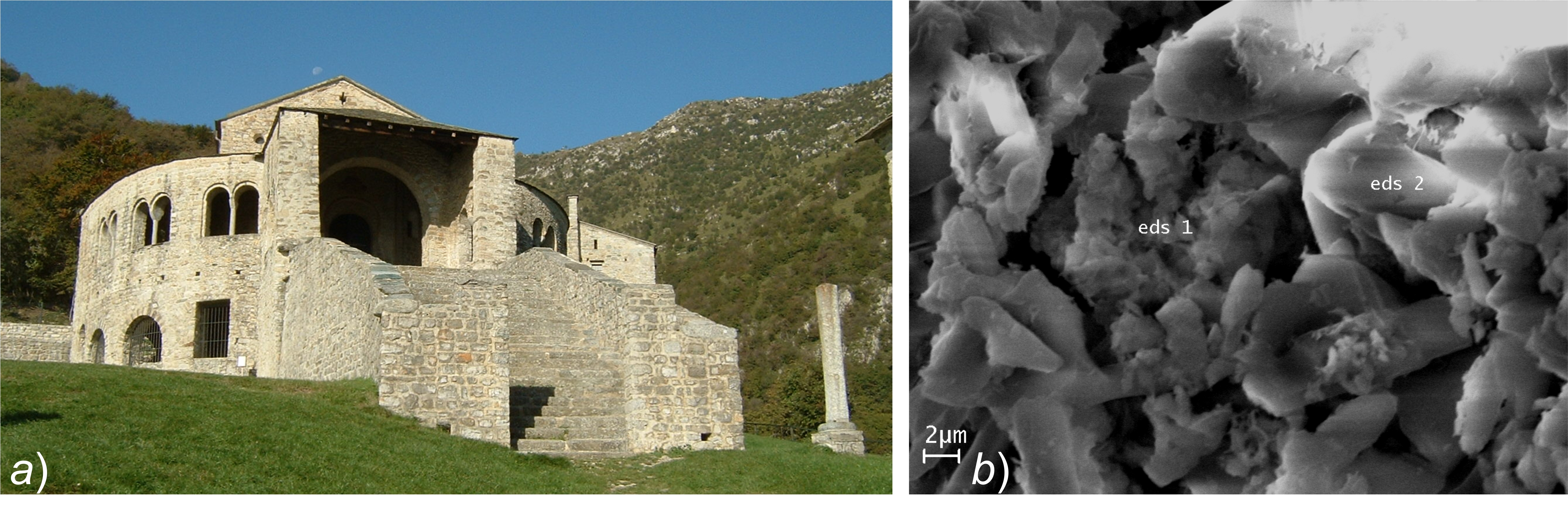

San Pietro al Monte Abbey a) and SEM observation of mortar samples b)

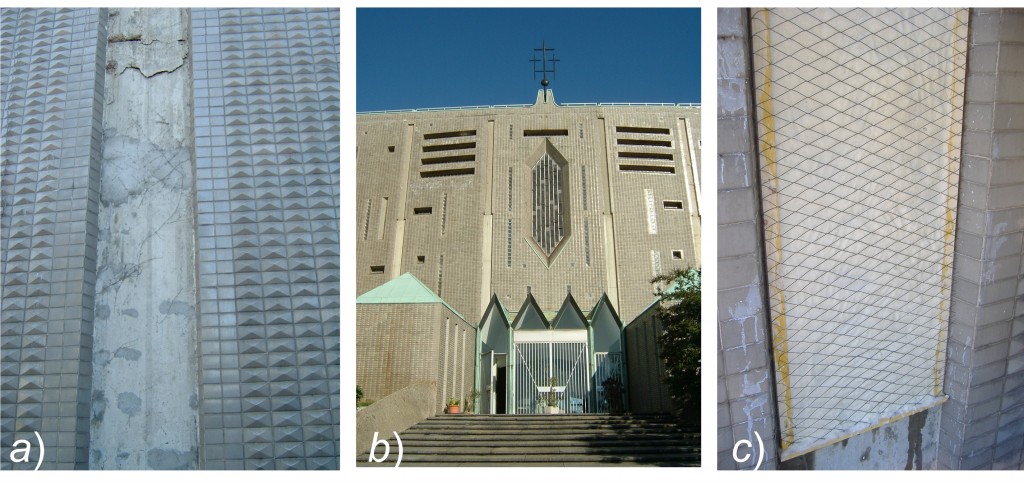

Preservation techniques for reinforced concrete structures

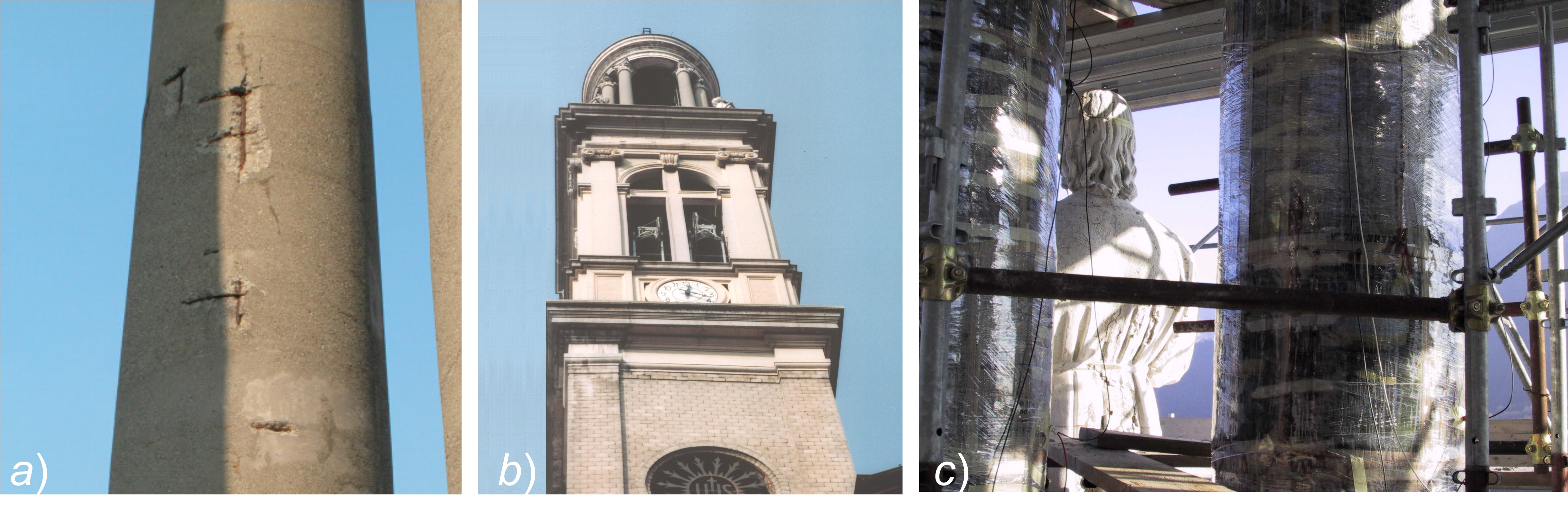

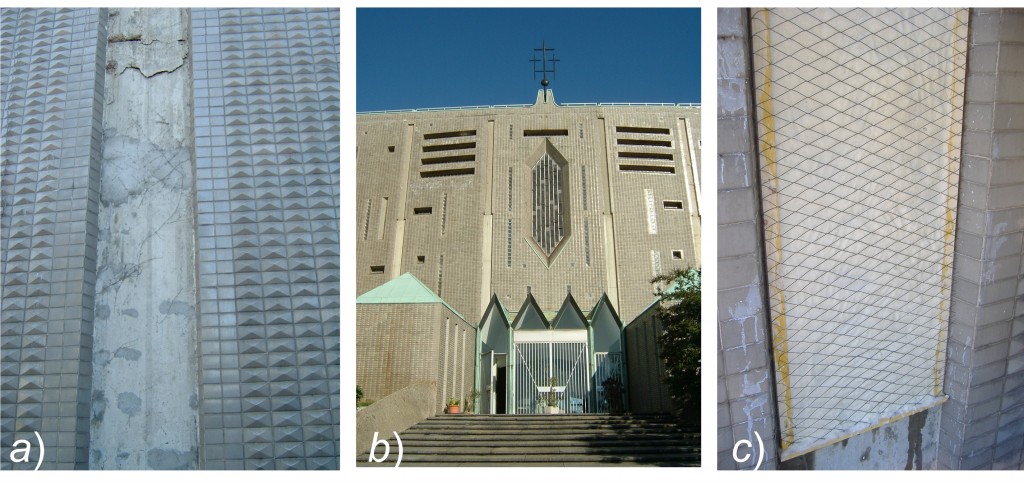

Several reinforced concrete structures, built around the middle of the previous century, have now reached the end of the service life and require maintenance intervention to repair possSeveral reinforced concrete structures, built around the middle of the previous century, have now reached the end of the service life and could require maintenance intervention to repair possible damages due to reinforcement corrosion. These interventions are required not only to restore the serviceability and the structural safety, but also to preserve the original materials and surfaces. This leads to the awareness that the conventional method, based on the removal of the non-protective concrete and its replacement with an alkaline mortar, although technically pursuable, should be carefully considered to make way to less invasive and more respectful methodologies. For instance, for the Church of Santa Maria Annunciata of the San Carlo Hospital in Milan, designed by Gio Ponti, surface hydrophobic treatments were tested together with the electrochemical realkalisation for the corrosion protection of the reinforced concrete pillars.

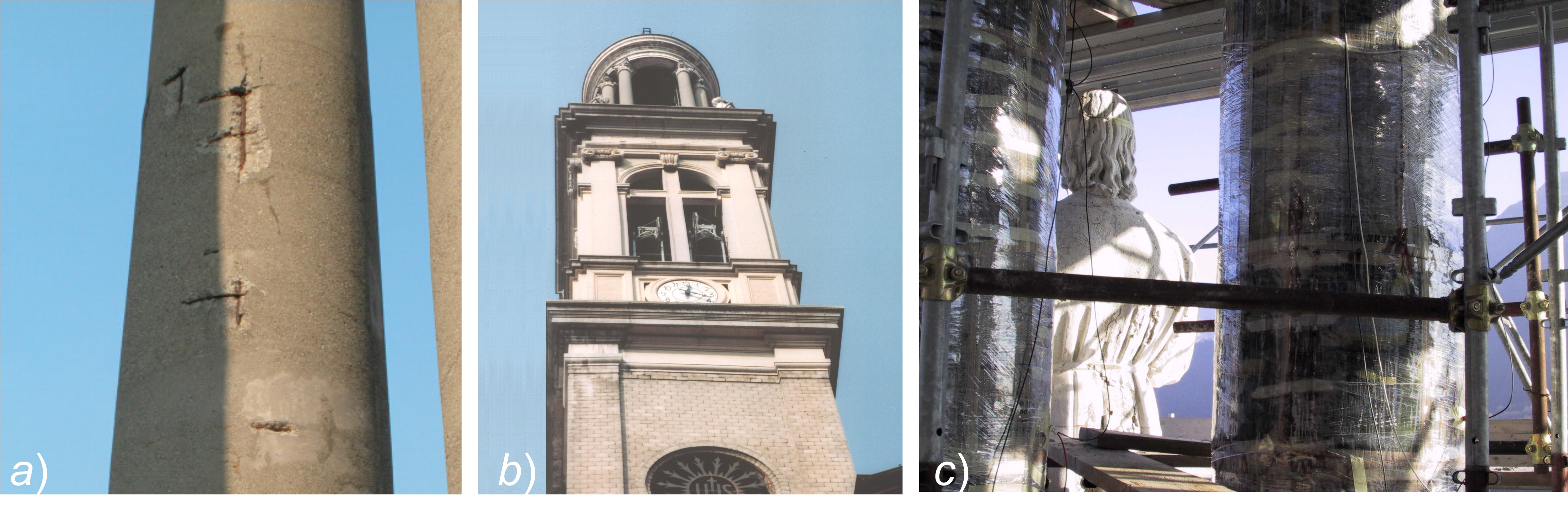

Bell of the Valmadrera Church and visual observation of a pillar (a-b) and application of the electrochemical realkalisation treatment (c)

Church of Santa Maria Annunciata of the San Carlo Hospital in Milano and details of a pillar (a-b) and application of the electrochemical realkalisation treatment (c)

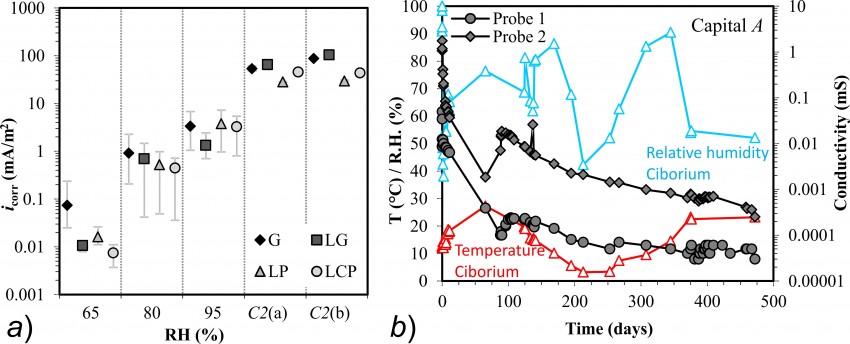

Corrosion of the metal inserts embedded in masonry

Another research topic of the mCD group is related to corrosion of metal inserts embedded in masonry on the consequent degradation of historic buildings. The effects of the composition of the materials in masonry and the humidity and temperature conditions on the corrosion behavior of metal inserts have been studied.

Ciborium of San Pietro al Monte (a), details of metal inserts visible on the inspected ciborium capital and collection of samples (both metallic and mortar or plaster) (b-c)

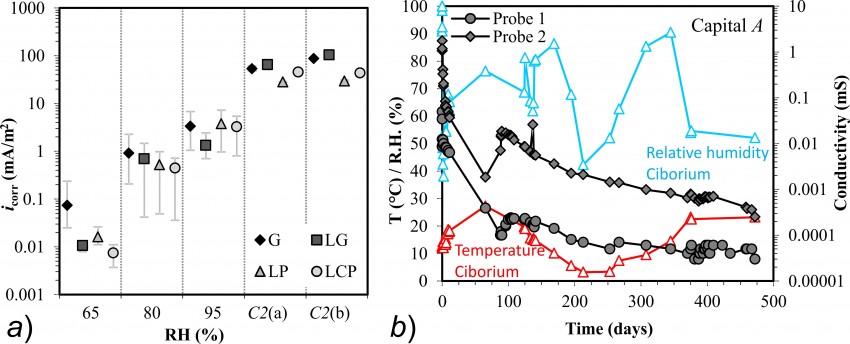

Corrosion rate (icorr) of metallic inserts embedded in different mortars (gypsum (G), lime and gypsum (LG), lime and pozzolana (LP) and lime and cocciopesto (LCP) mortars) as a function of relative humidity (a) and monitoring of electrical conductivity of the mortar with probes embedded in one of the capitals of Ciborium and thermo-hygrometric conditions inside the Abbey (b)